McLean, Va. (April 17, 2024) — A cutting tool becomes more than just a cutting tool when it unlocks transformative potential, and the at offers an entire building of new potential. Held at McCormick Place in Chicago from Sept. 9-14, IMTS is the premier industry event in manufacturing technology for 2024. Demonstrations at the show will emphasize automated systems that integrate multiple functions, enabling users to increase precision and boost productivity with existing staff.

“If a tool or workholding product or process can be digitized, you can count on exhibitors showcasing an innovative new solution at IMTS 2024,” says Peter R. Eelman, chief experience officer, ��ɫ��Ƶ – The Association For Manufacturing ��ɫ��Ƶ, which owns and produces IMTS. “High-technology cutting tools deliver a proven productivity payback, while advanced workholding combines accuracy and repeatability while increasing unattended run time. The Tooling & Workholding Sector will offer new ways of working more efficiently for shops of every size.”

Cellular Solutions

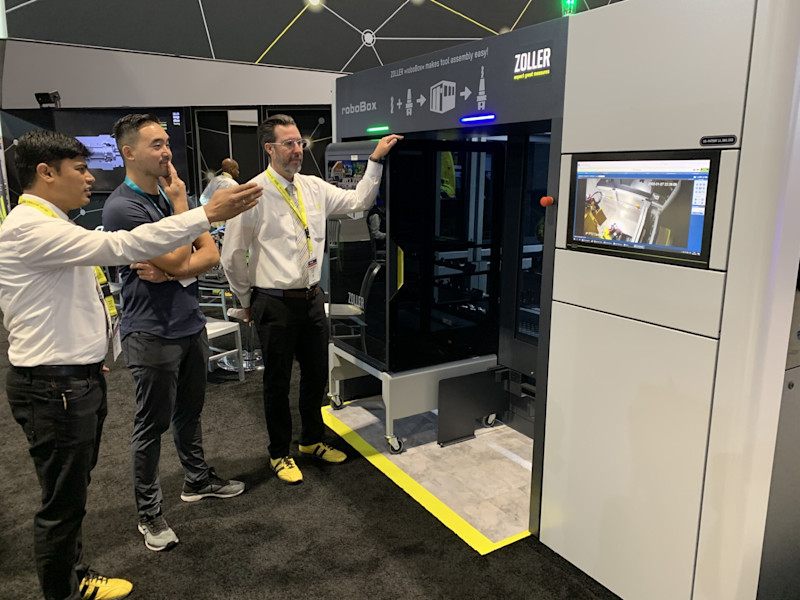

Rita Conroy-Martin, director of marketing & customer experience at ZOLLER (), says that “Success starts with good tool organization. At IMTS 2024, we will introduce the »coraMeasure LG« automated tool measurement system to improve precision and speed.”

The coraMeasure LG delivers tools (assembled in the company’s smartPallet system) to a linear robot that removes tools from the pallet and moves them to a ZOLLER »venturion« presetting and measuring machine. Each tool is identified with the ZOLLER »dChip« system, and tool data is stored in the ZOLLER z.One database.

“Automated tool management is at the center of the paradigm shift if we want to have an automated future in manufacturing,” says Conroy-Martin.

“The future is promising because there is so much opportunity for so many people if they invest in new technology,” says Brendt Holden, president of HAIMER USA. "For those who require large-scale tool shrinking and unshrinking, the new HAIMER Automation Cube One will make its IMTS premier in .” This fully automatic robotic cell can shrink fit a tool, measure it, and send the data to the machine tool in just 60 seconds. The Automation Cube One features a FANUC cobot for handling of tool assemblies and a Siemens Sinumerik One CNC control.

Wireless Advances

“Due to the skilled labor shortage, helping companies implement automation is becoming a larger part of what we do, especially as technology changes become more rapid,” says Larry Robbins, president - commercial division at SMW Autoblok Corp.

As an example of advances, Robbins points out the company’s contactless inductive coupler systems that can eliminate downtime associated with wear, as well as modify gripping force without unclamping the part. SMW Autoblok’s “e-motion” technology (showcased in ) can transmit energy (up to 1,500W) and data — contact-free — between stationary and moving components via an air gap. Products with e-motion technology include the MM electromechanical e-motion four-jaw chuck and the RT electromechanical e-motion tombstone with drive interfaces for up to eight universally configurable clamping devices, which can be controlled individually.

Finding Efficiencies

“Advances in tool design and workholding solutions continue to evolve. For many job shops, winning a new customer or extending run time often begins with a connection made in the Tooling & Workholding Sector,” says Eelman.

“If you are planning to attend IMTS 2024, you have already taken the first step towards finding products that will increase your shop’s productivity and profitability,” says Tom Sheridan, president at Royal Products (). The next step is using the planning tools on the to discover all of the companies that offer accessories to optimize performance. For example, the patented Royal Rota-Rack® is an automatic accumulator that can be used with any bar-fed CNC lathe to safely collect finished parts, providing hours of highly profitable, unmanned production. Other essential items include mist collectors or Quick-Grip™ Accu-Length™ collect chucks that help users get the most out of their machine tool investments.

Jay Simpson is co-owner of Multi-Axis Technologies, a small job shop focusing on high-mix, low-volume parts.

“We need to reduce our set-up time, and the best way we found to seek solutions was by attending IMTS and really diving into the Tooling & Workholding Sector,” he says. “We visited every booth and looked at the quick-change items and flexible solutions. Schunk () had the biggest family of products. We recently purchased the VERO-S modular quick-change pallet system, which reduces setup times and has a repeat accuracy of one ten thousandth. Now it is growing into this whole other subset of workholding solutions we needed.”

Tom Wheeler, president of Muskegon Tool () says that “When you can't find a standard, off-the-shelf tool, we can design a unique tool for your specific application and save your machining operation money. Customers tell us they have run millions of parts on the same tool —and that without that tool, they would not have been able to perform a particular operation.” As an example, Wheeler cites face grooving tools made to application-specific diameters and depths to improve the fit between mating parts or for an O-ring.

“Having attended IMTS for 20 years, I always see new things that we can incorporate into our own manufacturing, such as programmable surface grinders where the wheel can be dressed automatically,” says Wheeler. “IMTS is also a great way to broaden your contacts. It's good to know lots of other people because sometimes you need a favor or something unique. Connecting with people at the show helps you stay ahead of the latest innovations in the marketplace.”

The Tooling & Workholding Sector features 301 exhibitors occupying 186,245 sq. ft. of exhibit space in the West Building of McCormick Place.

to attend IMTS 2024 and . Use ��ɫ��Ƶ’s for the best hotel booking experience and room and price guarantees.

Social Media

Conversations within the IMTS community are continuing on social media:

X (formerly Twitter): or #IMTS

LinkedIn:

Facebook:

Instagram:

Media Notes

Download the IMTS 2024 logo and photos:

View the IMTS 2024 floor plan:

Watch the IMTS YouTube channel:

About IMTS – The International Manufacturing ��ɫ��Ƶ Show

IMTS – The International Manufacturing ��ɫ��Ƶ Show is where the creators, builders, sellers, and drivers of manufacturing technology come to connect and be inspired. Attendees discover advanced manufacturing solutions that include innovations in CNC machining, automation, robotics, additive, software, inspection, and transformative digital technologies that drive our future forward. Powered by ��ɫ��Ƶ – The Association For Manufacturing ��ɫ��Ƶ, IMTS is the largest manufacturing technology show and marketplace in the Western Hemisphere. With more than 1.2 million square feet of exhibit space, the show attracts visitors from more than 110 countries. IMTS 2022 had 86,307 registrants, featured 1,816 exhibiting companies, saw over 7,600 people attend educational events, and included a Student Summit that introduced the next generation to manufacturing. Be the change at IMTS 2024, Sept. 9-14, 2024. Inspiring the Extraordinary. IMTS.com.

About ��ɫ��Ƶ – The Association For Manufacturing ��ɫ��Ƶ

��ɫ��Ƶ – The Association For Manufacturing ��ɫ��Ƶ represents U.S.-based providers of manufacturing technology – the advanced machinery, devices, and digital equipment that U.S. manufacturing relies on to be productive, innovative, and competitive. Located in McLean, Virginia, near the nation’s capital, ��ɫ��Ƶ acts as the industry’s voice to speed the pace of innovation, increase global competitiveness, and develop manufacturing’s advanced workforce of tomorrow. With extensive expertise in industry data and intelligence, as well as a full complement of international business operations, ��ɫ��Ƶ offers its members an unparalleled level of support. ��ɫ��Ƶ also produces IMTS – The International Manufacturing ��ɫ��Ƶ Show, the premier manufacturing technology event in North America. ��ɫ��Ƶonline.org.